Danamin (M) Sdn Bhd is an inspection company located in Johor, Malaysia with more than 200 employees nationwide and is a long-term user of the HD-CR 35 NDT scanner.

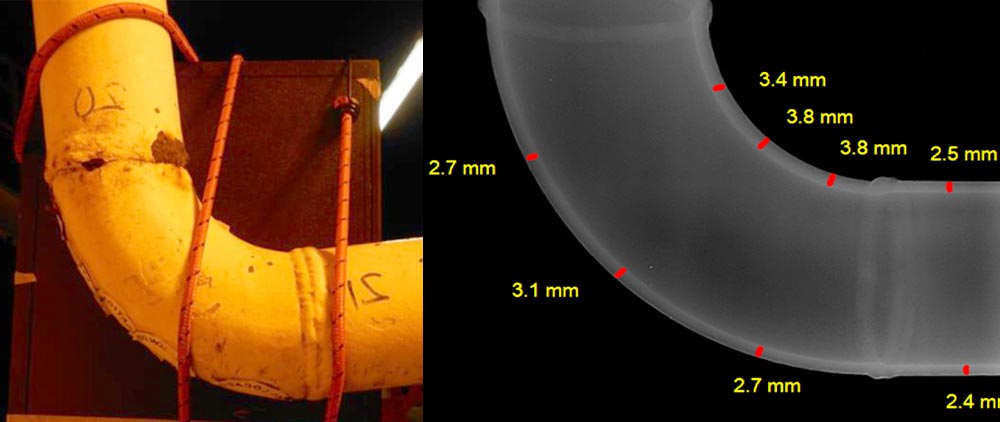

Danamin has been using the HD-CR 35 NDT system for pipe profile inspection since 2007 and initially acquired the system to fulfill an inspection requirement from Petronas Chemicals MTBE in Kuantan. Other customers taking advantage of Danamin’s computed radiography capability include BASF Petronas in Kuantan and Idemistsu Petrochemical in Johor.

The typical inspection workflow for Danamin is to expose the imaging plates on-site and then bring them back to headquarters for scanning, or if the location is far away, the radiographic team will scan the imaging plates at a temporary base. Both scanning and image evaluation is performed by a single fully-trained operator. Danamin uses either an Iridium-192 isotope source or X-ray with 35 x 43 cm white high-sensitivity imaging plates and typically acquires around 20 images per month using the system.

Comparing the HD-CR 35 NDT to conventional film radiography, “profile images are much better and there are significant time savings” commented Ms. Fatimah, Technical Manager at Danamin. Furthermore, “the system is very useful for urgent joint inspection jobs as the images are very sharp and the D-Tect software is easy to use”, she added. The use of imaging plates instead of film is also a huge advantage for Danamin: “Since imaging plates don’t have any expiry dates like film they are much easier for us to maintain. Sometimes film expires before the job is complete, especially for infrequently used sizes,” she explained.