Standard & 3D Digital Image Correlation (DIC) Solutions

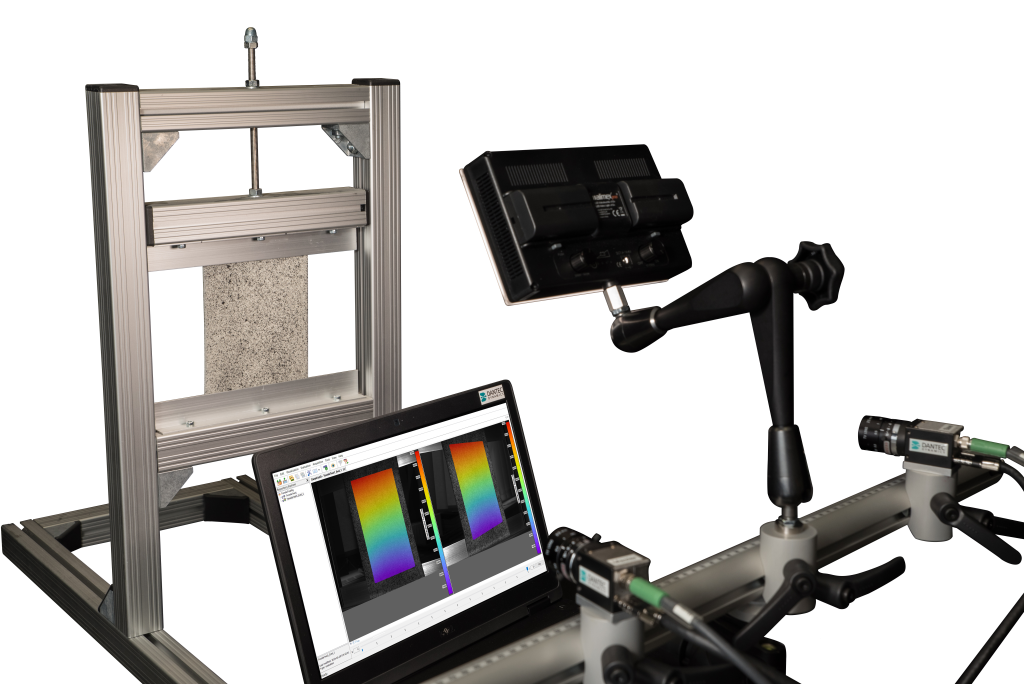

Digital Image Correlation (DIC) is a 3D full-field, non-contact optical technique to measure contour, deformation, vibration and strain on almost any material. The measurement principle is based on grey value digital images, that can determine the contour and the displacements of an object under load in three dimensions. The technique can be used with many tests including tensile, torsion, bending and combined loading for both static and dynamic applications.

The DIC method can be applied from very small (micro) to large testing areas – and the results are readily comparable with finite element analysis (FEA) results or strain gauges.

The features include: 3D Full-field, Real-time display of displacement and strain overlaid on live image; Real-Time Correlation with analog voltage output – evaluate, display and output data in real-time for interfacing with other equipment; Multi-camera system for up to 360 degree measurement around an object and simultaneous front and back side measurements (thinning); Measurement area < 1mm up to several square meters; Fast and easy automatic calibration procedure; Online feedback of accuracy and quality; All data with a confidence margin (error approximation); Full access to data using an open data format; Synchronous recording of analog data; Extended export to FEA software for comparisons; Different coordinate systems; High speed cameras up to 1,000,000 frames/sec.

EduDIC is a complete Digital Image Correlation (DIC) measurement system, designed as a simple and convenient educational training tool for academic courses in experimental solid mechanics. This easy-to-use system allows academic instructors to effectively present the optical measurement technique of DIC for materials testing to the engineers and scientists of tomorrow.

The 3D DIC System is used for determination of three-dimensional material properties in tensile, torsion, bending or combined tests. In addition, deformation and strain analysis can be applied to fatigue tests, fracture mechanics, FEA validation, and much more. Its flexible design enables a wide range of applications from microscopic investigations on microelectronic or biomedical materials to large scale measurements of aerospace, automotive, marine and railway components.

The 3D High-Speed Image Correlation System allows the full-field, non-contact and three-dimensional dynamic measurement of shape, displacements and strains on components and structures made from almost any material. The system is ideal for ballistics testing, fracture mechanics, shock excitations, the Hopkinson Bar test, or Impact Testing.

The Videoextensometer RTSS is perfectly suited for the determination of material properties in tension tests (longitudinal and transversal strain). The specimen’s deformation is measured contactlessly. Properties like Stress-strain curves, E-modulus and Poisson’s ratio are determined. Further analysis modules for the determination of crack length (e.g. long term tests) and crack areas (e.g. bondings) are available.

If you need a Digital Image Correlation solution, contact us for more information.