Ultrasonic Testing

In terms to meet the requirements of the NDT experts for advanced inspection technologies our portfolio includes ultrasonic inspection equipment.

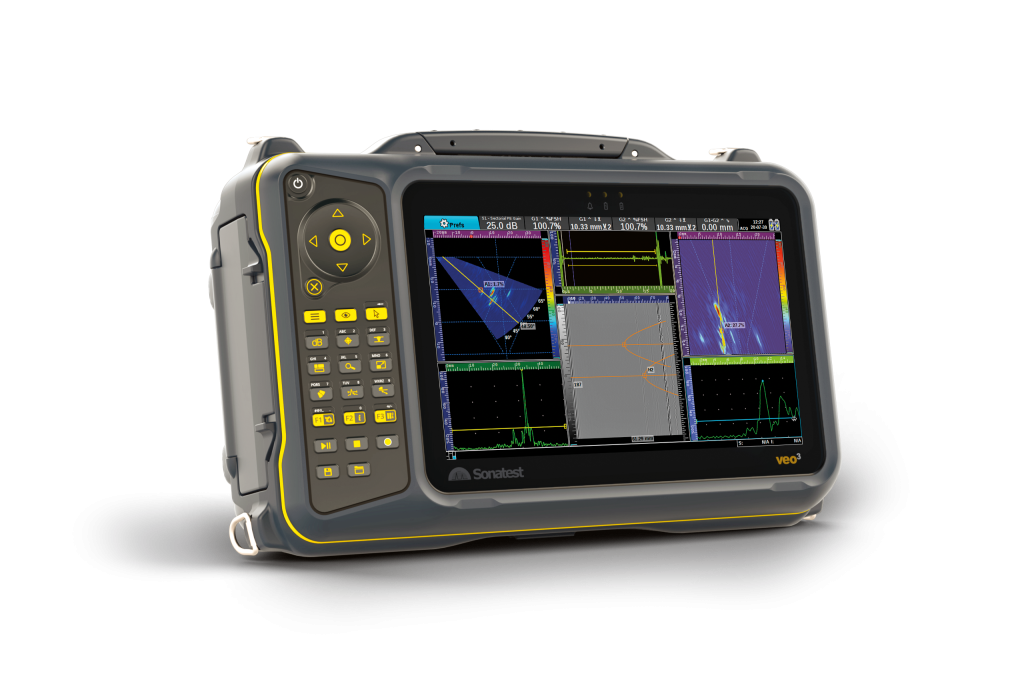

The product range includes field-proven high-resolution flaw detector offering PAUT, UT, TOFD and TFM in several channel configurations. The comprehensive range of portable ultrasonic and phased array flaw detectors provide the end user with unrivalled flexibility and performance. Along with Phased Array, other complementary techniques like the Time of Flight Diffraction (TOFD) and the Total Focusing Method (TFM) are also used to provide a more detailed and comprehensive 3D representation of a defect and global integrity of a part.

The UT product range is completed by an ultrasonic thickness gauges. Thickness measurement can be performed on most common engineering materials, such as metal, plastic and glass. In addition to the test equipment there is wide range of probes, wedges and scanners.

Ultrasonic scanners use high frequency sound waves to detect flaws and anomalies in the material of the component. Where anomalies are found, the sound waves create an echo which is evaluated by specialised testing instruments. Ultrasonic inspection can be manually performed, or fully integrated solutions can be created and configured to the requirements. Ultrasonic scanners provide accurate and efficient scanning – from corrosion mapping to weld inspections.

If you need a solution for UT – PA – TOFD – TFM inspection do not hesitate to contact us for more information.