Reliable quality control, and thus good preparation of the samples for analysis, is essential to prevent material failure. Errors can lead to serious safety issues and economic consequences.

For industries like Aerospace this is particularly important. Turbine blades, for example, are exposed to exceptionally harsh conditions resulting from a combination of high operating temperatures and radial tensile stresses. With reliable machines and consumables for materialographic sample preparation, high standards can be met to ensure correct analysis of all parts.

Make yourself familiar with QATM machines and consumables and learn how grinding discs can contribute to improved sample preparation.

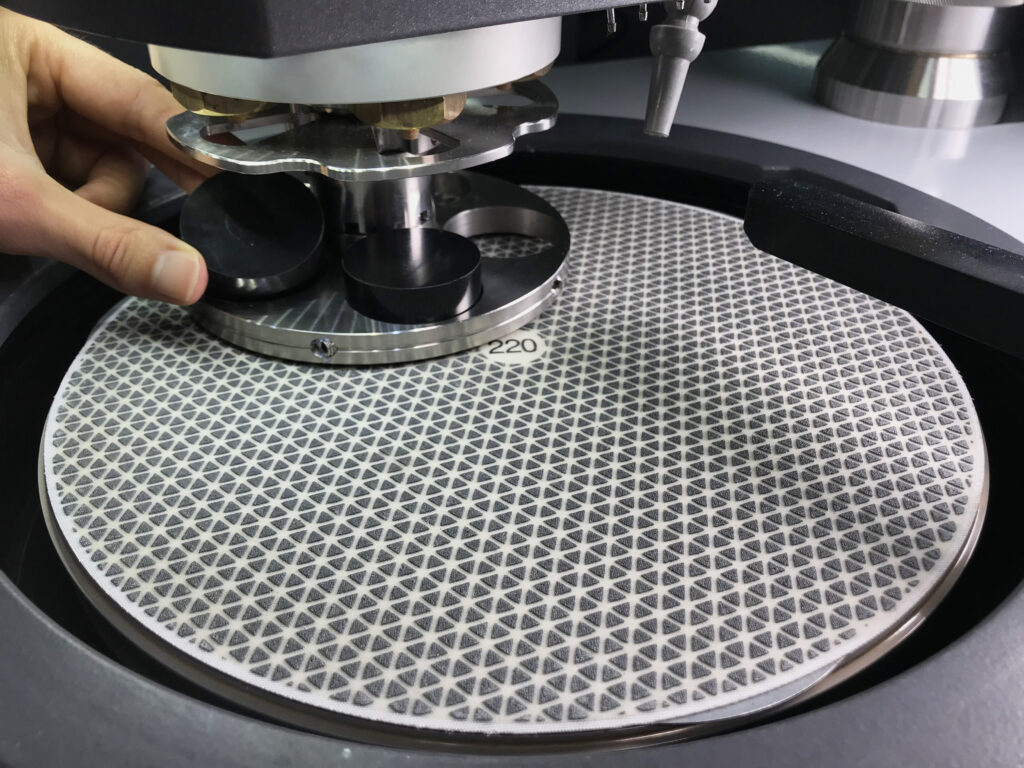

The new POLARIS grinding discs represent one of the latest innovations in sample preparation. POLARIS M is available with diamond grains of down to 3 µm to reduce preparation time and save polishing steps. POLARIS SIC utilizes common silicon carbide abrasive grains. Soft to medium-soft materials like aluminum, titanium, soft steels or composites like CFC can be easily prepared using POLARIS SIC or POLARIS M discs with convincing results.